We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

INVENTO 1600 Nm 1/2" pneumatic wrench

PromoProduct category: Impact wrenches

Price for: 1 PC.

- Details

-

INVENTO pneumatic impact wrench is a proven TIP-TOPOL private label tool.

The 1/2 inch composite impact wrench with twin hammer mechanism is an extremely powerful working tool which is indispensable in every vehicle workshop. With a maximum torque of 1,600 Nm, even stubborn bolts can be removed quickly and efficiently. It is perfect for most car repairs and seasonal tyre changes.

Design

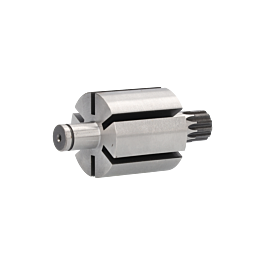

- Impact wrench with twim-hammer mechanism,

- the twin-hammer mechanism ensures durability and quick loosening of stubborn bolts even under tough working conditions,

- Tight oil bath lubrication ensures that the impact mechanism does not wear excessively.

- The robust glass fibre reinforced composite housing helps protect the user's hand from the cold and reduces vibration for less user fatigue.

- The 6-blade impeller provides faster motor start-up and improved high torque performance,

- Three "forward" torque settings.

- Full torque power for moving "backwards".

- Convenient trigger for better operator control.

Intended use

Impact wrench is designed for all work related to loosening or tightening bolts, especially those corroded or seized. For use in:

- mechanics, e.g. during suspension repair work

- tyre fitting - indispensable during seasonal tyre changes, allows for quick and easy loosening of seized bolts.

- production lines

Main advantages:- high quality of workmanship - use of durable materials

- robust mechanism - tight oil bath lubrication ensures that the impact mechanism does not wear excessively.

- robust glass-fibre reinforced composite housing reduces vibrations and protects the user's hand from the cold and ensures a firm grip on the wrench even under tough working conditions.

- the 6-blade rotor ensures quick start-up and better performance with high torque

- 3-level tightening power adjustment - 50%, 70% and 100% for 870 Nm

- 1-level adjustable torque for 1,600 Nm

- convenient and ergonomically located trigger for better control

- ergonomics - the wrench weighs just over 2 kg, which makes it convenient to hold and easy to use

- perfectly balanced.

- Technical data

-

- Drive:: 1/2” (13 mm)

- Rotational speed: 8,500 rpm

- Maximum torque: 1600 Nm

- Operating torque 870 Nm

- Air inlet: 1/4”

- Hose inner diameter: 10 mm

- Maximum pressure: 6.3 bar

- Average air consumption: 170 L/Min

- 3-level forward rotation speed control

- Weight: 2.1 kg

- Spare Parts

-

- Warranty

-

Warranty: 12 months

- Safety

-

- Responsible Producer:

-

TIPTOPOL SP. Z O.O.

ul. Kostrzyńska 33

62-010 Pobiedziska

Poland

sklep@tiptopol.pl

+48618152200

Mechanical risks

The product has movable parts that can cause a variety of mechanical hazards during operation, which can lead to serious injuries.

Crushing and crushing: There is a risk that the moving parts of the product will crush or crush the body. It can lead to serious injury or permanent injury.

Cuts and punctures: Cuts, cuts, and even deeper injuries can occur if the user comes into contact with sharp edges or product components.

Impact and Fall Injuries: These can occur when objects fall over and fall from a height or are moved in an improper and dangerous manner. This can cause serious injuries, including broken bones and head injuries.

Trapping: If a body part becomes trapped between moving parts, it can lead to serious injury and loss of limbs.

Vibration: Exposure to prolonged vibration while using the device can damage muscles and nerves. This can lead to vibration syndrome, causing pain and dysfunction in the limbs.

To minimise these risks, it is recommended to use appropriate personal protective equipment, regularly inspect and maintain the equipment, and follow all manufacturer's recommendations for safe use and health and safety (Occupational Health and Safety) regulations.

Explosion Risk

When using certain products, such as pressurized vessels or chemicals, explosion hazards can occur, which can lead to serious consequences.

Gas explosions: These can occur when flammable gases such as propane, methane, butane or fuels are used or stored in improper conditions. This can lead to fires, property damage, and injury to people or even death.

Pressurized substances: Pressurized substances, such as gas or liquids, can explode due to rising temperatures or improper storage. The explosion of such substances can lead to serious injuries, property damage and a threat to life.

In order to minimize the risk of explosion, it is recommended to read the device's manual, information on the packaging and in the safety data sheets, use appropriate protective equipment, regularly inspect and maintain the equipment, and comply with all safety procedures and health and safety (Occupational Health and Safety) regulations.

Thermal risks

When working with heat-generating equipment, a variety of thermal hazards can occur, which can lead to serious consequences.

Burns: Contact with hot surfaces or materials can lead to skin burns. This can cause pain, skin damage, and in more serious cases, require medical treatment.

Fires: Heat-generating appliances can start fires if they are misused or overheated. Fires can cause property damage, personal injury and life-threatening conditions.

Overheating of appliances: Appliances can become overheated as a result of prolonged use or improper ventilation. This can lead to damage to the equipment and also pose a fire hazard.

Explosions and explosions: Heat-generating devices can cause explosions, particularly if they are working with flammable or pressurized substances. This can lead to extensive damage and danger to life and health.

Loss of equipment smoothness: Heat-generating devices can operate less efficiently when exposed to excessive heat. This can lead to equipment failure and the need to repair or replace them.

To minimize thermal risks, it is recommended to read the device's user manual, information on the packaging and in the safety data sheets, regular inspection and maintenance of the equipment, the use of appropriate personal protective equipment, and compliance with the manufacturer's recommendations for the safe use of heat-generating equipment.

Ergonomic risks

When working with heavy objects and in situations requiring prolonged use of force, a variety of ergonomic hazards can occur, which can lead to serious health consequences.

Muscle and joint overload: Muscle and joint overload can occur when lifting, carrying, or handling heavy objects. It can lead to pain, muscle tears and strains, joint injuries, and even structural damage to the body.

Poor posture at work: Working in the wrong posture, such as a hunched posture or twisted posture, can lead to tension in the muscles and spine. This can cause chronic back, neck and shoulder pain and back problems.

Prolonged use of force: Prolonged performance of activities that require a lot of physical effort can lead to fatigue and overloading the body. This can lead to exhaustion, muscle injuries and reduced work efficiency.

Prolonged vibration: Prolonged exposure to vibration, especially with the use of power tools, can lead to nerve and muscle damage. This can cause vibration syndrome, manifested by pain, numbness and loss of sensation in the limbs.

Monotony and repetitive movements: Performing the same movements for a long time can lead to micro-injuries and overloads. This can lead to injuries such as carpal tunnel syndrome, tendonitis and other musculoskeletal conditions.

To minimize ergonomic risks, it is recommended to use appropriate lifting techniques, ergonomic tools and workstations, and regular breaks and stretching exercises.

Acoustic risks

When working in a noisy environment and using noisy tools or machinery, a variety of acoustic hazards can occur, which can lead to serious health consequences.

Permanent hearing loss: Prolonged exposure to high levels of noise can lead to permanent hearing damage. This can cause gradual hearing loss, which can be irreversible and lead to communication difficulties.

Temporary hearing loss: Short-term exposure to very loud noises can cause temporary hearing loss. Though usually reversible, frequent episodes can lead to permanent damage

Fatigue and stress: Prolonged noise can lead to mental and physical fatigue, as well as increase stress levels. This affects work efficiency, cause problems with concentration and increase the risk of errors.

Sleep disturbances: Working in a noisy environment can affect sleep quality, especially if noise is also present outside of working hours. This can lead to chronic fatigue, poor overall health, and reduced regeneration capacity.

Irritation and irritability: Constant noise can lead to irritation and irritability, affecting well-being and interpersonal relationships. This can lead to workplace conflicts and a reduced quality of life.

To minimise acoustic risks, it is recommended to wear hearing protection, comply with the regulations on maximum noise levels in the workplace, use noise-cancelling headphones and have regular hearing check-ups.

Environmental risks

A variety of environmental hazards can occur during the use and disposal of products, which can lead to serious consequences.

Environmental pollution: Products, especially those containing chemicals or plastic, can contribute to soil, water, and air pollution. This can lead to the degradation of ecosystems, groundwater and surface water pollution, and negative impacts on human and animal health.

Improper disposal of products: Improper waste management can lead to the uncontrolled spread of toxins and contaminants. This can result in severe environmental pollution, risks to public health, and the loss of valuable natural resources through a lack of recycling.

Electronic waste (e-waste): Electronic products, when not properly disposed of, can become a source of e-waste containing harmful chemicals and heavy metals. This can lead to soil and water contamination, as well as pose a risk to human and animal health.

To minimise environmental risks, it is recommended to manage waste appropriately, including segregation and compliance with environmental regulations.