We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

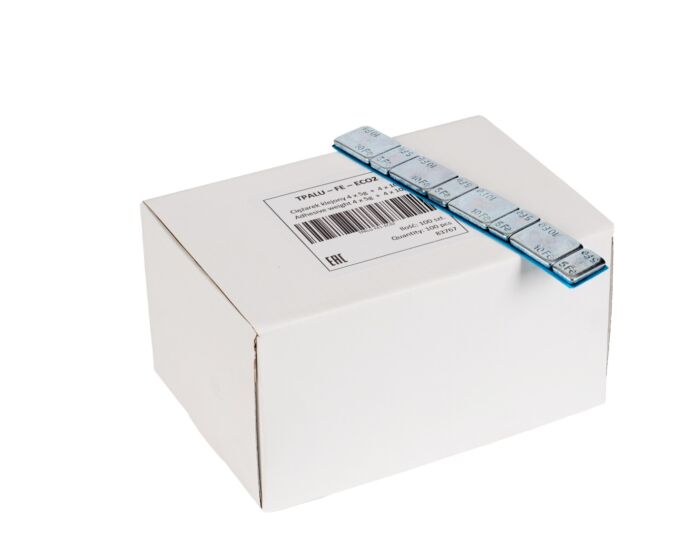

Adhesive Wheel Weight ALU SLIM ECO – 4x5g + 4x10g

PromoProduct category: Steel (Fe) wheel weights

Price for: 100 per box

Adhesive steel wheel weights, rounded and zinc-coated, designed for alloy wheels. SLIM type with a wide blue protective tape. The package contains 100 strips, each weighing 60g (4x5g + 4x10g). The weight height is 3.8 mm.

- Details

-

Adhesive Steel Wheel Weights – SLIM Type for Alloy Rims (Silver Zinc-Coated)

Product Description:

Adhesive steel wheel weights with a rounded shape, designed for alloy wheels. SLIM type weights with a silver zinc coating and wide blue protective tape.

The standard package includes 100 strips, each weighing 60 grams. Each strip contains 8 segments – 4 weights of 5 grams and 4 weights of 10 grams.

Thanks to their elegant, rounded design, the weights fit perfectly onto the rim, ensuring precise balancing of alloy wheels.

Each weight features a wide blue protective tape that shields the adhesive layer.Durability

The weights are zinc-coated to protect against corrosion and adverse weather conditions.

A strong adhesive tape ensures a durable and secure attachment to the rim.

To remove the weights, a dedicated scraper tool is recommended.Fast & Safe Installation

These adhesive weights are mounted using double-sided tape, making them safe for use on alloy rims.

Compared to clip-on weights, adhesive weights greatly reduce the risk of damaging the rim surface.Ease of Use

Thanks to their compact size, rounded and optimal shape, and flexible adhesive tape, the weights easily conform to almost any rim.

The wide blue protective film allows for quick application without removing safety gloves.Accurate Balancing

Each strip weighs 60 grams and is divided into 8 segments: 4 x 5g and 4 x 10g, allowing precise balancing.

Elegant Appearance

The rounded shape and silver zinc finish make the weights visually appealing, especially on light-colored rims.

With a thickness of just 3.8 mm, they remain nearly invisible once mounted.Proven Quality

As a manufacturer of wheel weights, we offer only top-quality products.

Every production batch is tested in our in-house laboratory according to strict quality standards.Application Purpose:

Adhesive wheel weights are used to correct wheel imbalance by applying the appropriate amount of counterweight.

This method provides a quick and effective way to correct wheel mass distribution.Application Range:

Balancing of alloy wheels for passenger cars, SUVs, and light commercial vehicles.

Mounting Instructions:

-

Thoroughly clean and dry the surface where the weight will be applied. Use suitable cleaners and tools to avoid rim damage.

-

Cut the desired weight segment from the strip using a knife.

-

Do not remove the protective tape prematurely.

-

Stick the weight precisely to the marked balance point on the rim.

-

After removing the protective film, avoid touching the black adhesive tape.

-

Ensure the weights are evenly placed and aligned parallel to the rim edge.

-

Press the weights onto the rim, starting from the center toward both ends.

-

- Technical data

-

- Material: Steel

- Protective coating: Zinc-plated

- Type: Adhesive

- Mounting method: Sticking onto the rim

- Application: Alloy wheels

- Height: 3.8 mm

- Shape: Rounded

- Color: Silver

- Protective tape: Blue, wide

- Weight of each segment: 5 grams and 10 grams

- Weight of one strip: 60 grams

- Package weight: 6 kg

- Number of weights per strip: 8 pcs

- Number of strips per package: 100 pcs

- Number of packages: 1 package

- Responsible entity: TIP-TOPOL

- Catalogue index: TPALU-FE-ECO2

- Code: TPALU-FE-ECO2

- Warranty

-

Warranty: 12 months

- Safety

-

- Responsible Producer:

-

TIPTOPOL SP. Z O.O.

ul. Kostrzyńska 33

62-010 Pobiedziska

Poland

sklep@tiptopol.pl

+48618152200

Mechanical risks

The product has movable parts that can cause a variety of mechanical hazards during operation, which can lead to serious injuries.

Crushing and crushing: There is a risk that the moving parts of the product will crush or crush the body. It can lead to serious injury or permanent injury.

Cuts and punctures: Cuts, cuts, and even deeper injuries can occur if the user comes into contact with sharp edges or product components.

Impact and Fall Injuries: These can occur when objects fall over and fall from a height or are moved in an improper and dangerous manner. This can cause serious injuries, including broken bones and head injuries.

Trapping: If a body part becomes trapped between moving parts, it can lead to serious injury and loss of limbs.

Vibration: Exposure to prolonged vibration while using the device can damage muscles and nerves. This can lead to vibration syndrome, causing pain and dysfunction in the limbs.

To minimise these risks, it is recommended to use appropriate personal protective equipment, regularly inspect and maintain the equipment, and follow all manufacturer's recommendations for safe use and health and safety (Occupational Health and Safety) regulations.

Chemical risks

When using chemical products, a variety of chemical hazards can occur, which can lead to serious consequences.

Chemical spills: These can occur due to packaging damage, misstorage, or misuse. Spills lead to environmental contamination, property damage and exposure of human health to toxic substances.

Chemical reactions: Uncontrolled chemical reactions can occur when different chemicals interact. This can lead to explosions, fires or the release of harmful gases that can be dangerous to health and life.

Corrosion and degradation of materials: Certain chemicals can cause corrosion and degradation of materials they come into contact with. This can lead to a weakening of the structure of materials, which in turn can cause equipment and structures to fail.

Poisoning: Improper use of chemical products can lead to inhalation, ingestion, or absorption through the skin. This can lead to poisoning, which can have serious health effects and even be life-threatening.

To minimize these risks, it is recommended to read the information on the packaging and in the safety data sheets, use appropriate personal protective equipment, follow safety procedures, regularly inspect equipment in which chemicals are used to check for tightness and correct closure of packaging, and appropriate storage and use of chemicals.

Environmental risks

A variety of environmental hazards can occur during the use and disposal of products, which can lead to serious consequences.

Environmental pollution: Products, especially those containing chemicals or plastic, can contribute to soil, water, and air pollution. This can lead to the degradation of ecosystems, groundwater and surface water pollution, and negative impacts on human and animal health.

Improper disposal of products: Improper waste management can lead to the uncontrolled spread of toxins and contaminants. This can result in severe environmental pollution, risks to public health, and the loss of valuable natural resources through a lack of recycling.

Electronic waste (e-waste): Electronic products, when not properly disposed of, can become a source of e-waste containing harmful chemicals and heavy metals. This can lead to soil and water contamination, as well as pose a risk to human and animal health.

To minimise environmental risks, it is recommended to manage waste appropriately, including segregation and compliance with environmental regulations.